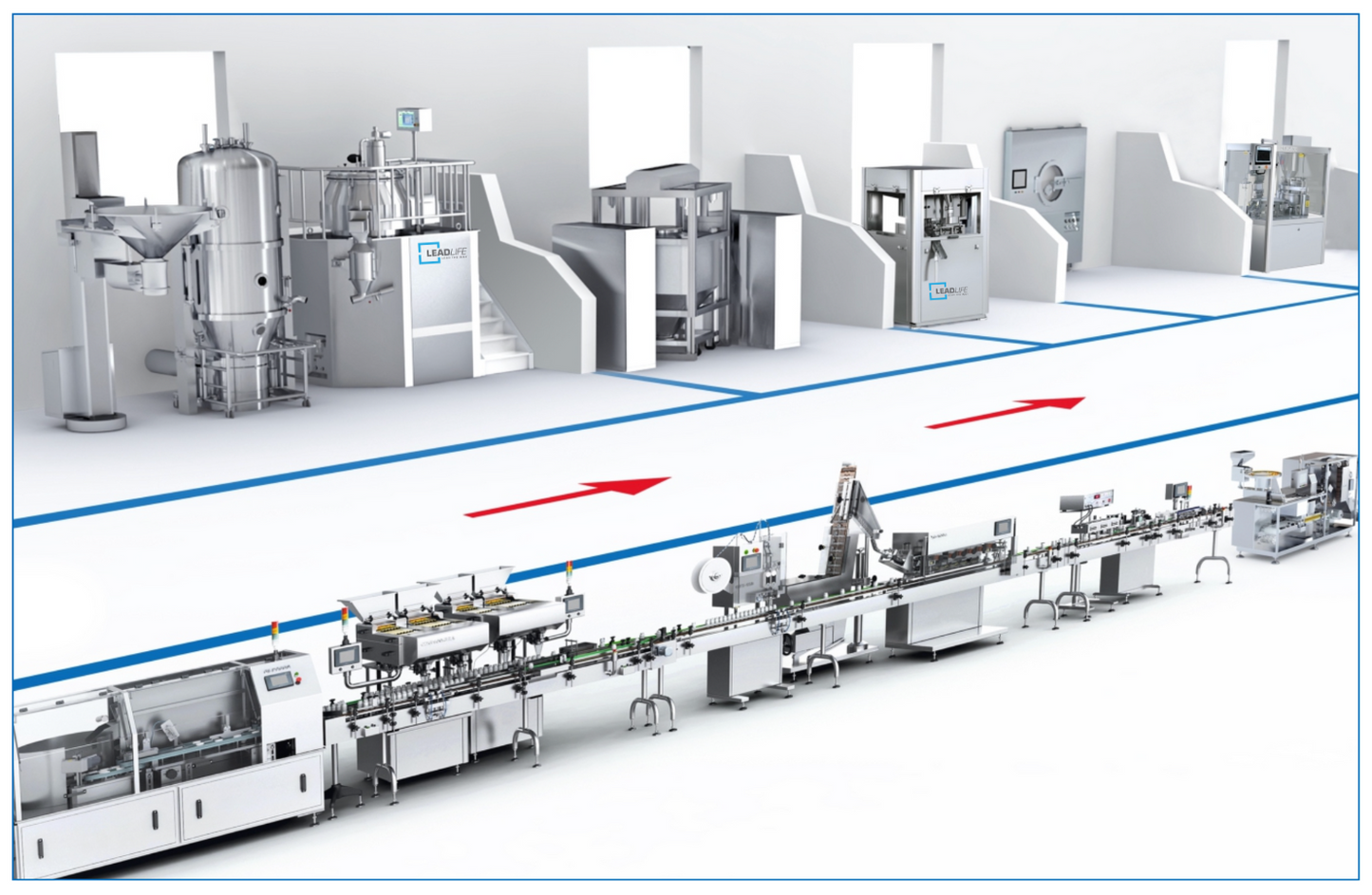

Automatic Capsule & Tablet Counting and Bottling Line

High-accuracy pill counting + full bottling workflow for capsules and tablets. This integrated line combines bottle feeding, electronic counting, dust extraction, rejection, capping, induction sealing, labeling, and outfeed in one GMP-ready system. Built for nutraceutical and pharma teams that need consistent throughput, fast changeovers, and local support.

Also called: capsule counting machine, tablet counter, pill counter, counting and bottling line.

Key benefits

-

Accurate counts with multi-channel sensors and auto-rejection for under/over counts.

-

Scalable throughput: configure channels and lanes to meet target BPM/CPM.

-

Fast changeovers: recipe recall for bottle size, count, and speed parameters.

-

Clean operation: integrated dust extraction and anti-static control.

-

Full line control: synchronized conveyors with bottle detection and jam prevention.

-

GMP-ready: stainless contact parts, batch reports, and validation docs available.

-

US support: spares and remote diagnostics from our North America team.

Typical workflow

- Bottle unscrambler → infeed conveyor

- Electronic capsule/tablet counter with dust removal

- Under/over-count rejection station

- Desiccant/cotton inserting (optional)

- Screw capping or press-on capping

- Induction sealing & cap inspection (optional)

- Front/back/360° labeling with lot/date printer

- Outfeed accumulation table

Specs at a glance

| Item |

Value |

| Counting accuracy |

Up to 99.9% (application-dependent) |

| Channels / lanes |

Configurable (e.g., 12–60 channels) |

| Supported products |

Hard gelatin & HPMC capsules; tablets/softgels (shape-dependent) |

| Bottle sizes |

Round/oblong, typical 30–300 cc (others on request) |

| Power |

110V/220V, 50/60Hz (per module) |

| Air requirement |

Clean dry air for pneumatics (spec per configuration) |

| Compliance |

GMP-ready; IQ/OQ docs available |

| Options |

Desiccant/cotton inserter, induction sealer, vision, weight check, metal detector |

What’s included

- Configured counting module(s) with bottle gating and rejection

- Conveyors with sensors, guides, and speed control

- Capping, sealing, and labeling modules as specified

- Setup, run-in, and operator training (onsite or remote)

- Spare parts kit and US-based support

Recommended pairings

FAQs

What throughput can we expect?

Throughput depends on channels/lanes, bottle size, and target count. Tell us your SKU mix and we’ll size the line for your CPM/BPM target.

Can the line run both capsules and tablets?

Yes—most configurations support both. Change parts and recipes speed up product changeovers.

Do you provide installation and validation docs?

Yes—installation & training are available, with IQ/OQ documentation upon request.

What utilities are required?

110/220V power (module-dependent) and clean dry air for pneumatics. We’ll provide a utilities list with your quote.

Contact us to schedule a live demo.